Pre-sterilized syringe labels: a smarter solution for aseptic operations

Key takeaways

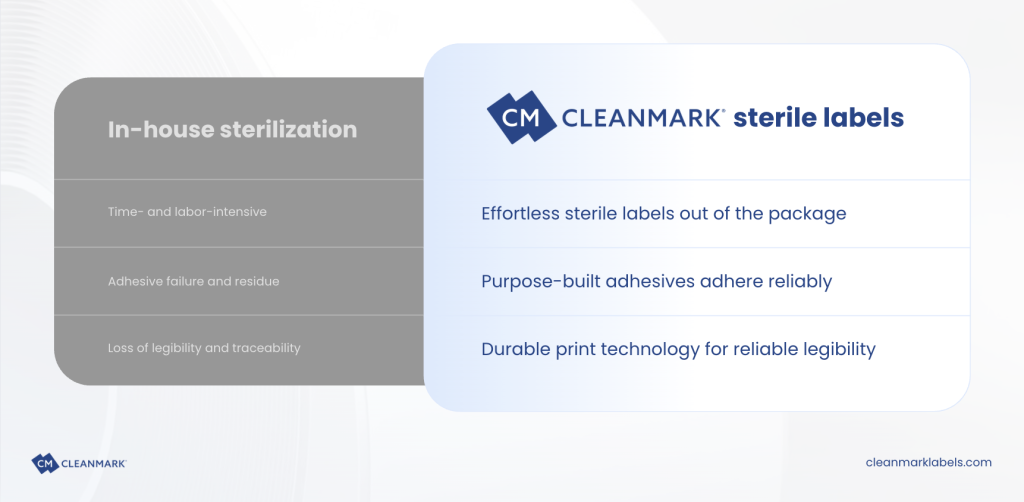

- Sterilizing syringe labels in house may seem efficient, but it introduces major risks: adhesive breakdown, print distortion, contamination, and regulatory non-compliance.

- Maintaining sterility is difficult without validated packaging, sterilization indicators, and tightly controlled handling procedures.

- In-house methods strain technician time, delay batch prep, and increase QA workload.

- Pre-sterilized syringe labels eliminate these risks by arriving ready-to-use, with validated sterility and reliable print and adhesive performance.

- For teams focused on compliance, throughput, and patient safety, pre-sterilized labels are the safer and more efficient choice.

Sterile syringe labels are essential, but which method is best?

When contamination is the biggest threat to your company’s success, it makes sense that every single component that enters your aseptic and clean environments should be carefully vetted — even something as small as a syringe label. Yet many sterile manufacturing and compounding companies still rely on in-house sterilization methods to prepare labels for use in aseptic and clean spaces.

At first glance, sterilizing syringe labels internally might seem like a practical workaround. In reality, it introduces significant risks. Adhesives and inks can degrade, sterile outcomes are inconsistent, and the burden of process validation consumes your team’s time and energy.

Pre-sterilized syringe labels reduce risk and keep your team’s focus where it should be — on your product. In healthcare, medical device, and pharmaceutical industries where compliance, safety, and efficiency matter, the difference isn’t just technical. It’s strategic.

Where syringe labels fail — and what it costs you

Syringe labels are a small, but essential, component. And unfortunately, they’re prone to failure. The tightly curved surface of a syringe makes edge lift more likely. Moisture, extreme temperatures, and chemical exposure all put adhesives to the test. And, sterilization or surface cleaning can smear and smudge printing.

Any or all of these failures can create uncertainty about product identity, dosage, or expiration, leading to delays, rework, discarded batches, or even worse, risks to patient safety. In other words, a faulty label isn’t just cosmetic. It’s a fundamental threat to the success of your product.

The risks of in-house label sterilization

It’s not surprising that many companies are tempted to bring syringe-label sterilization in house. On the surface, making label sterilization part of in-house operations seems like it could reduce costs and increase efficiency. But it doesn’t. Here’s why.

Adhesive degradation

Adhesive degradation is a primary concern. Many commercial label adhesives are not formulated to withstand sterilization temperatures, humidity, or radiation. Even if labels appear to adhere at first, edge lift, bubbling, or full detachment can occur days later, especially under refrigerated or high-humidity conditions common in sterile workflows. Poor adhesion compromises both identification and sterility. Once a label lifts, it can trap contaminants or shed particles directly into the cleanroom environment.

Risks

- Adhesive softening or breakdown under sterilization conditions

- Edge lift or flagging during cool-down or freezer storage

- Bubbling from trapped moisture or off-gassing

- Total label detachment during application or transport

- Residue transfer that interferes with container integrity

Consequences

- Loss of product identity

- Incomplete or missing compliance information

- Surface contamination and particle shedding

- Rejected batches or delayed release due to relabeling or reinspection

Print distortion

Print distortion is another possible failure point. Direct thermal print, for example, can smear or ghost under heat and pressure. Paper labels may fade or disintegrate entirely, especially in moist or high-humidity cycles. Even synthetic label stocks can experience legibility loss during autoclaving, EtO, or gamma sterilization if not coated or laminated properly.

Faded or illegible labels introduce the risk of misidentification or lost traceability, especially in high-stakes applications like narcotics, biologics, or patient-specific doses.

Risks

- Smearing, blurring, or fading of ink

- Label breakdown that reduces or destroys legibility

- Curling or lifting that distorts print

Consequences

- Inability to verify drug identity, dose, or expiration

- Loss of critical patient or batch tracking information

- Regulatory citations for illegible or missing label content

- Delays, rework, or disposal of products

- Increased risk of medication errors in clinical settings

Contamination

Achieving and maintaining sterility is difficult. Without a validated, closed-loop process — including packaging designed for sterilization, sterilization process indicators, and post-process integrity checks — there is no way to confirm a label is truly sterile at point-of-use. Even if bioburden is reduced in the chamber, post-process handling during transfer and storage peeling can reintroduce contamination.

Risks

- Contamination during transfer

- Packaging failure

- Ambient air exposure

- Glove contact or mishandling

Consequences

- Loss of sterility assurance

- Batch rejection or recall

- Regulatory non-compliance

- Increased risk to patient safety

Non-compliance

The regulatory burden of in-house sterilization of syringe labels is significant and often includes:

- Bioburden testing on label lots

- Dose mapping and exposure validation

- Packaging integrity testing

- Ongoing process controls and revalidation after any change to materials, cycle, or equipment

Few facilities — especially at the hospital or small-batch scale — have the resources to maintain this level of documentation and quality control.

Risks

- Incomplete or missing validation documentation

- Failure to meet sterility assurance level (SAL) requirements

- Unmonitored changes to label stock or sterilization conditions

- Use of packaging materials not validated for sterilization

- Inconsistent or undocumented reprocessing practices

Consequences

- FDA 483 observations or warning letters for inadequate material control

- Delays or rejections during audits and inspections

- Increased QA burden and resource strain

- Loss of product release confidence and regulatory trust

- Potential liability if a contamination event is traced to labeling

Operational inefficiency

In-house sterilization of syringe labels consumes technician time, delays batch prep, and introduces multiple points for error. It’s not just about whether the label survives the sterilization cycle. It’s about whether it maintains functional sterility and legibility under real-world handling conditions.

Risks

- Extended prep time due to pre-sterilization labeling logistics

- Batch delays caused by sterilization equipment bottlenecks

- Increased manual handling steps and handoffs

- Resource drain on QA/QC staff for reinspection or troubleshooting

- Repeated relabeling or label replacement due to post-cycle failures

Consequences

- Slower overall batch turnaround times

- Reduced technician availability for critical compounding tasks

- Increased labor costs per unit due to workflow inefficiencies

- Production scheduling disruptions in high-throughput environments

- Lower operational capacity and throughput over time

When all these factors are taken into account, in-house label sterilization is rarely the smart choice it appears to be. It shifts the burden of validation and sterility assurance from the supplier, who is equipped to manage it, onto internal teams who often aren’t. The result is higher risk and lower efficiency in your operations.

Why pre-sterilized syringe labels are safer and smarter

If you’re put off by the many risks above, pre-sterilized syringe labels offer a streamlined, validated alternative that reduces risk and improves efficiency across aseptic operations.

Pre-sterilized syringe labels, like CleanMark’s, arrive ready to use, with documented sterility and full traceability. Our sterile labels for syringes are manufactured under controlled conditions and sterilized using validated processes, typically gamma irradiation. This eliminates the need for internal validation and reduces QA burden while aligning cleanly with GMP and USP <797> expectations.

Because they are specifically engineered for sterilization, CleanMark sterile labels maintain their physical integrity and print performance post-sterilization in real-world use. Our custom syringe label adhesives are designed to adhere reliably to tight curves, withstand extreme temperatures during sterilization and storage/shipping, and are resistant to alcohol and chemical wipes. And, our packaging and shipping process preserves sterility during handling and storage.

Operationally, CleanMark sterile syringe labels remove multiple risk variables from the production process. With our pre-sterilized labels, there’s no need to wait on sterilizer availability, no technician time lost to prepping and validating label sterilization cycles, and no second-guessing whether a label is sterile or will stay adhered under real-world conditions.

When you do the math, the simplicity and reliability of pre-sterilized labels make them not just the safer option, but also the most efficient operationally.

Order your CleanMark sterile syringe labels now

Whether you know exactly what you need or could use some support from our engineering team to design the perfect custom syringe label for you, we’re here to help. Schedule a consultation or chat with one of our legal experts now (icon to your left) to get started!

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

The automation label: materials and construction matter

Why your automated label applicator and labels should be designed together

How automated labeling changes your label needs

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.