What does the Food Traceability Rule mean for your labeling procedures?

Key takeaways

- The Food Traceability Rule is scheduled to come into effect on January 20, 2026.

- The FTR, under the Food Safety Modernization Act (FSMA), introduces new traceability requirements for certain types of food.

- Companies producing products covered under the FTR must track Key data elements (KDEs) at all Critical Tracking Events (CTEs).

- These companies must also have a traceability plan that outlines their procedures for capturing and storing KDEs.

- FTR-optimized labels are a key tool to maintain compliance and increase efficiency under the new regulations.

The Food Traceability Rule is almost here. Are you ready?

On January 20, 2026, the Food Traceability Rule is scheduled to come into effect under the Food Safety Modernization Act (FSMA). These new requirements by the FDA increase the complexity of food tracing and require precise labeling to maintain compliance.

What does this mean for you? For many companies, it means labels will have to be rethought prior to the new year. An experienced labeling partner who can engineer custom labels specifically for new FTR requirements is the key to keeping your supply and processing operations running smoothly and within regulations.

The CleanMark team is standing by to help, but in the meantime, here are some actionable tips for determining how the FTR applies to you and what you need to do to achieve labeling compliance before the deadline.

1. Does the FTR apply to me?

The FTR doesn’t apply to every single food product. Only products listed on the FDA’s food traceability list (or products made with those ingredients in their listed forms) must comply with the FTR. Here’s the list as published in March 2025. You can access the full, most current list here.

- Cheese (made from pasteurized milk), fresh soft or soft unripened

- Cheese (made from pasteurized milk), soft ripened or semi-soft

- Cheese (made from unpasteurized milk), other than hard cheese

- Shell eggs

- Nut butters

- Cucumbers (fresh)

- Herbs (fresh)

- Leafy greens (fresh)

- Leafy greens (fresh-cut)

- Melons (fresh)

- Peppers (fresh)

- Sprouts (fresh)

- Tomatoes (fresh)

- Tropical tree fruits (fresh)

- Fruits (fresh-cut)

- Vegetables (fresh-cut)

- Finfish, histamine-producing species (fresh, frozen, and previously frozen)

- Finfish, species potentially contaminated with ciguatoxin (fresh, frozen, and previously frozen)

- Finfish, species not associated with histamine or ciguatoxin (fresh, frozen, and previously frozen)

- Smoked finfish (refrigerated, frozen, and previously frozen)

- Crustaceans (fresh, frozen, and previously frozen)

- Molluscan shellfish, bivalves (fresh, frozen, and previously frozen)

- Ready-to-eat deli salads (refrigerated)

Even if you produce one of the foods on the food traceability list, you’ll also want to check out this handy exemption questionnaire to determine if another aspect of your business may exempt you from following FTR requirements.

2. What do I have to track and when?

The FTR focuses on two key elements:

- Critical tracking events (CTEs)

- Key data elements (KDEs)

Critical tracking events are points in the supply and production process that require traceability information to be collected. Harvesting and shipping, for example, are both CTEs.

Key data elements are the specific types of data you’re required to collect They’re tied to specific CTEs. You can access the full list of KDEs along with additional details here.

What is a traceability lot code (TLC)?

The FDA defines the TLC as a “descriptor, often alphanumeric, used to uniquely identify a traceability lot within the records of the firm that assigned the traceability lot code.” In other words, it’s the identifier that stays with the lot throughout its lifecycle.

According to the FDA, TLCs must be assigned when the food is

- initially packed (for raw agricultural commodities not obtained from a fishing vessel)

- received by the first land-based receiver (for food obtained from a fishing vessel)

- Transformed

Dig deeper >> FDA Traceability Lot Code webpage

What’s a traceability plan and how do I make one?

Your Traceability Plan (TP) should outline your food tracing procedures, how you assign TLCs, a point of contact, and other details depending on your industry. Full details are outlined in section 1.1315 of the FTR. You can also find examples of industry-specific traceability plans on the FTR website.

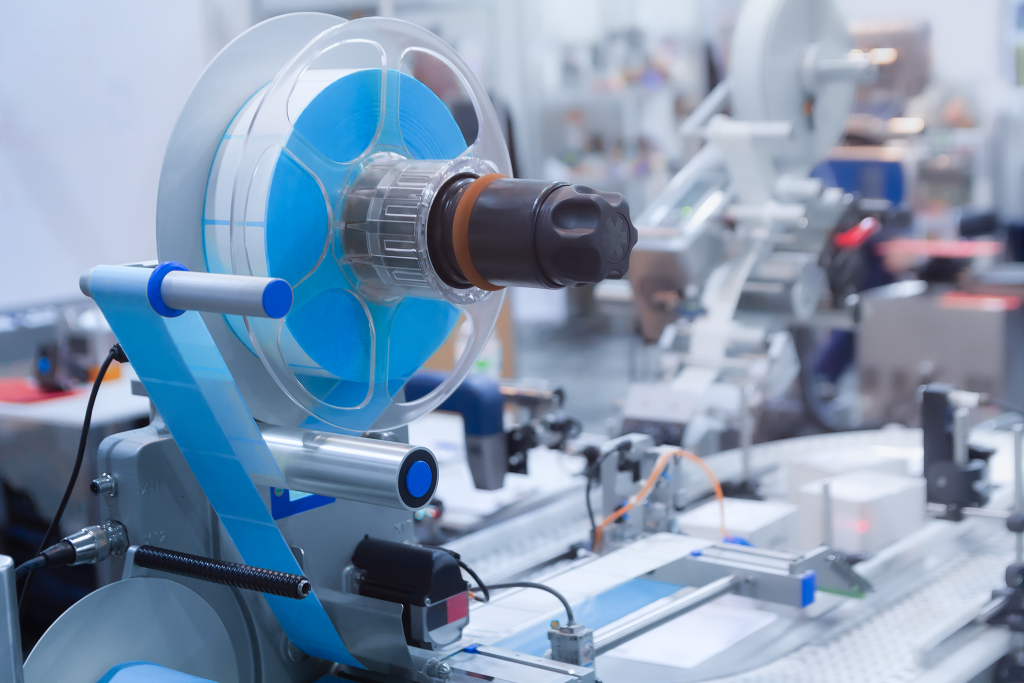

How do I optimize my labeling procedures for FTR compliance?

Labels are a key tool for capturing KDEs and communicating that information into your traceability records as outlined in your traceability plan (more on that below). Working with a labeling partner, like CleanMark, who has experience designing labels for high-throughput operations in harsh environments is the best way to ensure compliance and speed production.

Extreme durability

Tracking labels are only as good as they are durable. If they fall off or become illegible, you’re out of compliance and risk both customer safety and big government fines. CleanMark’s durable labels are designed to withstand extreme temperatures, moisture, and chemical exposure while staying clearly readable and firmly adhered.

Printing flexibility

Choosing labels that are preprinted with static information, like logos and handling instructions, but are also optimized for on-site printing delivers both speed and accuracy — key for maintaining efficiency and compliance.

Variable printing

Pre-printing known variable information, like TLCs, is another time saver. The key is to work with a labeling partner who can guide you to the most efficient combination of factory and on-site printing to meet your compliance and operational needs while keeping your processes moving smoothly.

Take the stress out of FTR labeling

It’s good to have a general idea of what you’re looking for in an FTR-compliant label, but honestly, you have higher priorities — like running your business!

CleanMark’s engineering team takes the stress out of adjusting for the FTR, or any other regulation for that matter. We look at all the details, learn about your unique processes and environment, and then design a label that performs.

Schedule a consultation to learn more, or take our LabelBuilder for a spin to see what’s possible!

Resources

- FSMA Final Rule on Requirements for Additional Traceability Records for Certain Foods

- § 1.1315 What traceability plan must I have for foods on the Food Traceability List that I manufacture, process, pack, or hold?

- US FDA: Traceability Lot Code

- Food Traceability Rule: Critical Tracking Events (CTEs) and Key Data Elements (KDEs)

- Exemptions to the Food Traceability Rule

- The FDA Food Traceability Rule At-A-Glance

- Food Safety Modernization Act (FSMA)

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

The automation label: materials and construction matter

Why your automated label applicator and labels should be designed together

How automated labeling changes your label needs

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.