Sterile labels

Tired of sterilizing labels in house? CleanMark’s custom sterile labels take the risk and effort out of labeling in regulated aseptic environments.

Order now

- Give us some initial information

- Review and test your label

- Production and shipping

Sterile labels increase productivity in sensitive environments

Labels are small but essential elements of operations. They facilitate tracking, control quality, prove compliance, and ensure consistency in your processes. They can also be a source of contamination. CleanMark sterile labels get you all the benefits with none of the risks.

Processed in a clean environment

Our state-of-the-art cleanroom processing facility and double bagging reduce contamination.

Sterilized with gamma irradiation

Deep-penetrating gamma irradiation ensures our sterile labels are free of microorganisms so your sensitive environments are protected.

No bacteria-attracting adhesive residue

Our sterile labels stay put when they’re supposed to and remove cleanly when designed to do so — so you’re never left with a sticky surface.

Durability in harsh lab environments

CleanMark’s sterile labels are durable against a range of challenging environmental conditions, ensuring no contaminating particles are shed.

Boost efficiency with labels that are clean and sterile

Highly regulated products often pass through both clean and aseptic environments during manufacturing. CleanMark dual-purpose clean, sterile labels give you the best of both worlds, ensuring compliance, minimizing risk, and speeding production.

Make labeling easier — order your sterile labels now

Explore our full range of sterile labels and sterilization indicators

Autoclave indicator labels

Easy-to-read results based on steam, temperature, and time

ETO indicator labels

Color change under pressure, exposure, temperature and duration consistent with sterilization

Gamma indicator labels

Color change under irradiation dose process consistent with sterilization

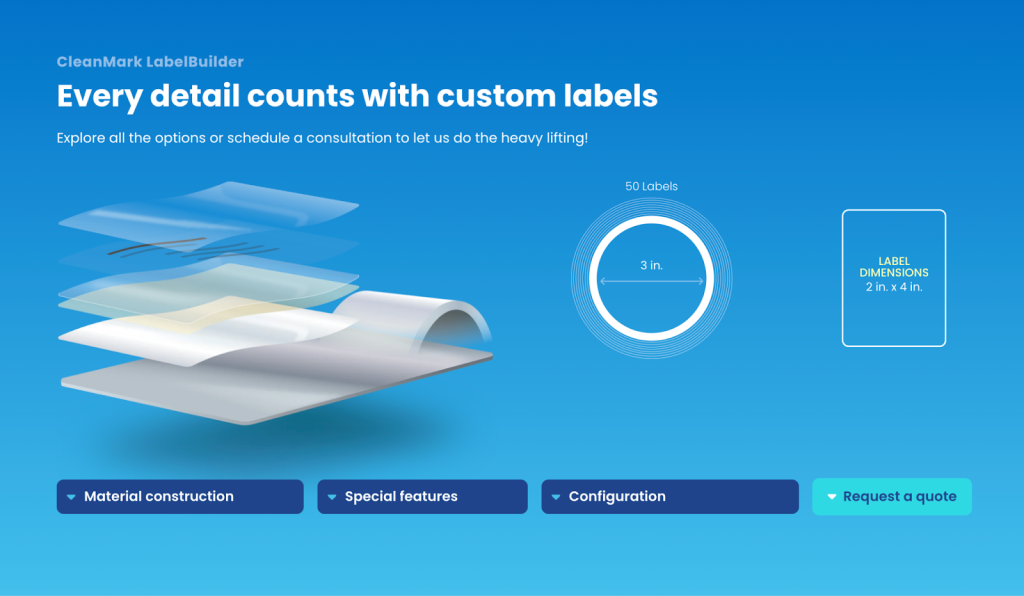

There’s more to a label than sterility

The best labels don’t just perform one function — they’re a constellation of features that allow the label to function perfectly in your unique environment and processes. CleanMark has the expertise to ensure your label has the right combination of features to perform flawlessly.

Let us design the perfect sterile labels for you

What sets CleanMark apart from other label producers is our expertise and level of service. Our label experts work with you to understand the exact parameters of your operational needs and then design a label that meets every one of them — even if we have to invent something new to make it happen.

Join the list of innovative companies partnering with CleanMark

Looking for more information about labeling technology and applications?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

Optimizing lab labels for high-performance aseptic operations: hybrid sterile + cleanroom-compatible labels

Medication labels: why customization matters

What is the ISO standard for implantable medical device labeling requirements?

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.