CleanMark Labels: 40 years solving the impossible

When Lon Martin founded CleanMark Labels in 1978, he wasn’t chasing easy sales — he was chasing problems no one else could solve. And customers noticed. What began as a one-man label business quickly evolved into one of the industry’s most respected sources of custom-engineered labeling solutions.

The advent of the cleanroom label

Today, CleanMark is the leader in cleanroom-compatible labels. But when CleanMark first encountered a need for clean labeling technology at Siltec in the 90s, cleanroom-specific labels weren’t being marketed.

Siltec needed labels that wouldn’t contaminate their sensitive cleanrooms by shedding particles — something no one else had been able to provide them. CleanMark responded by engineering a label from synthetic materials, packaged in a way that preserved cleanliness throughout production and handling. From the adhesive to the liner to the packaging process, everything had to be reimagined — and our team was primed with the practical and material know-how to think outside the box.

The cleanroom label we developed for Siltec changed how semiconductor, pharmaceutical, and medical-device manufacturers approach labeling in sensitive environments, and we continue to advance and perfect our cleanroom labels today to meet the most stringent cleanroom parameters.

Material science as a competitive edge

CleanMark’s ability to solve problems at the material level has become our defining strength. From cryogenic storage to extreme heat environments, our engineers choose — or develop — components that are uniquely tailored to our customers’ environments and procedures.

From tiny, self-extinguishing information labels for PCMCIA cards to new insert-molding processes for chemical-resistant auto component labels, our team has proven that decades of real-world experience paired with deep technical understanding is an unstoppable combination.

Whether it’s cleanroom environments, cryogenic storage, or high-heat applications, CleanMark’s process is consistent: ask the right questions, evaluate every layer of the material construction, and test rigorously. Time and again, this has revealed hidden factors others missed — like how gating configurations in a mold can cause label ink to lift, or how packaging methods can introduce particulate contamination in clean environments.

When customers tell us other suppliers have said, “It can’t be done,” CleanMark steps in with a different answer: “Let’s make it happen.”

The CleanMark commitment

Today, CleanMark continues to partner with leading manufacturers in semiconductors, pharmaceuticals, medical-devices, automotive, and more.

We aren’t in the business of selling labels. We’re in the business of solving labeling challenges that others walk away from. Customers don’t come to CleanMark for a cookie-cutter label. They come with a challenge and leave with a solution. That’s our CleanMark commitment.

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

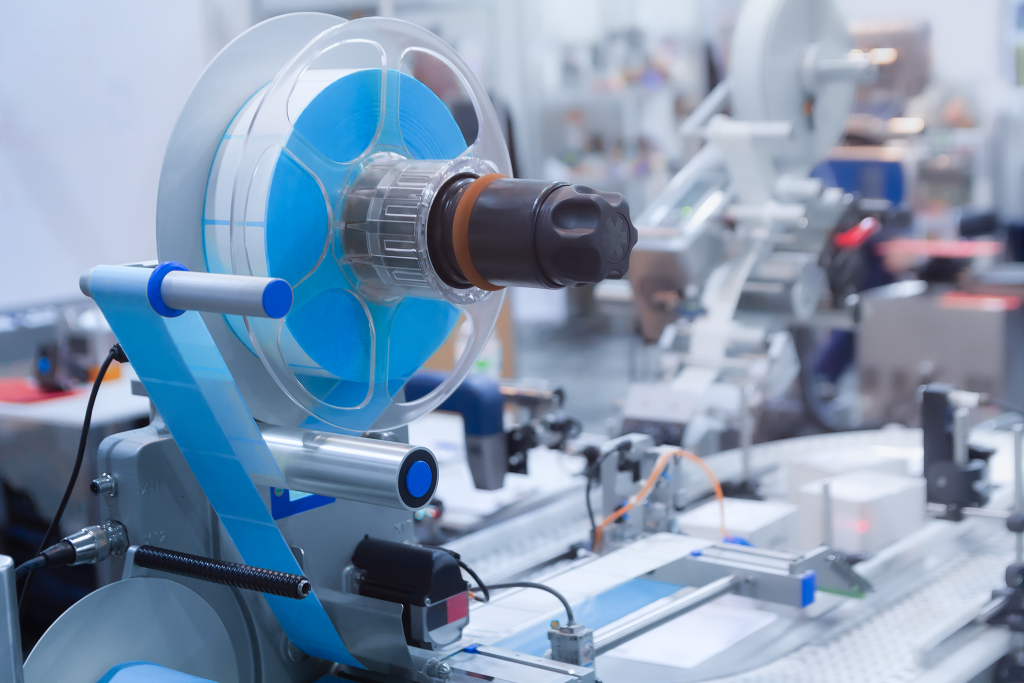

The automation label: materials and construction matter

Why your automated label applicator and labels should be designed together

How automated labeling changes your label needs

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.