Harness the power of the CleanMark LabelBuilder

Key takeaways

- The CleanMark LabelBuilder eliminates the guesswork of stock catalogs by letting you define labels around your actual process requirements.

- It converts real-world use cases into technical specs, ensuring your labels perform in demanding environments like cleanrooms, freezers, or sterilization cycles.

- The tool helps engineers, QC professionals, and purchasing agents align on a single set of requirements, reducing errors, rework, and wasted time.

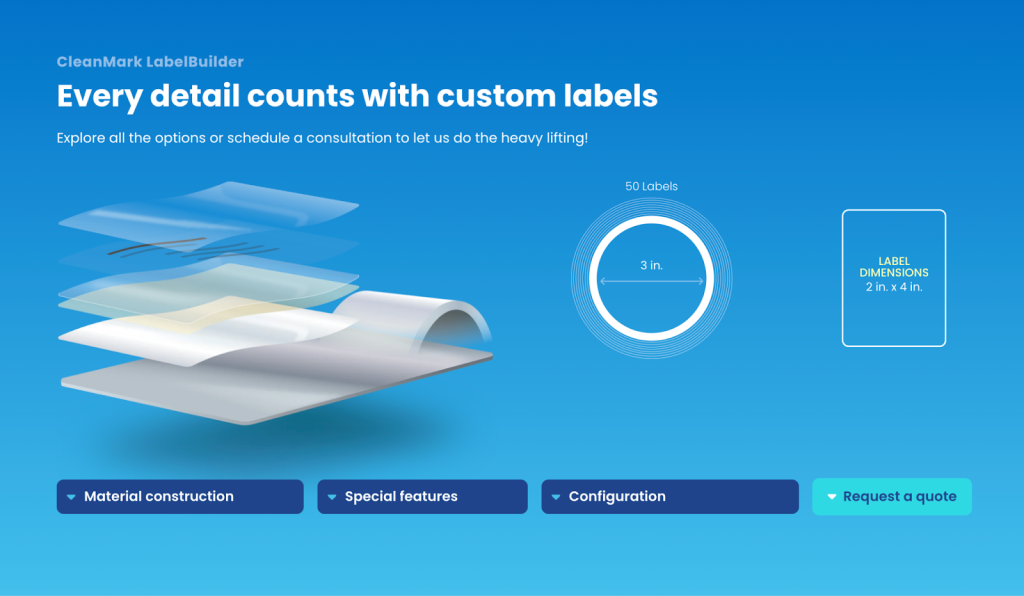

- With guided selections, visual layer displays, and expert review, you can be confident your final label design will meet compliance and performance needs.

Don’t settle. Build something new.

It’s frustrating to know what type of label you need and not be able to find it in a stock catalog. Instead, you settle for what’s available and either adjust your processes or try to fit a square peg into a round hole. The result is rarely good. That’s why we created the CleanMark label builder.

It’s a powerful online tool that allows you to define the requirements for your custom labels quickly and clearly. The LabelBuilder centers your environment, your workflow, and your compliance needs, capturing your detailed technical and use requirements so our engineers can design a label that exceeds your expectations from day one.

What the CleanMark LabelBuilder does

The CleanMark LabelBuilder acts as both a checklist and a design conversation starter. It doesn’t expect you to know the technical name of every substrate or adhesive, but it does walk you through the critical decision points that determine whether a label succeeds or fails in your environment.

Simplify the decision-making process

Instead of overwhelming you with dozens of variables, the LabelBuilder organizes choices into logical categories.

Translate use cases into specifications

By prompting you to describe where and how a label will be used, the tool converts real-world conditions into technical requirements.

Bridge technical and purchasing needs

Engineers see their performance requirements reflected, QC teams see compliance considerations covered, and purchasing gets a clear specification for sourcing.

Streamline design and production

Every submission is reviewed by a CleanMark engineer, so you don’t have to worry about making a wrong selection — your inputs guide the conversation but don’t lock you in.

Why it’s valuable for engineers, QC, and purchasing

When choosing a new labeling solution, it can be tough to marry every stakeholder’s requirements. Using the LabelBuilder saves time, reduces errors, and ensures that all stakeholders get what they need:

Engineers

Translate process realities into label design via a structured process. Instead of hunting through vendor catalogs or testing off-the-shelf products that fail in extreme environments, define the actual demands of your processes — like sterilization cycles, cryogenic storage, or abrasive cleaning solvents — and get a solution engineered to handle them.

QC professionals

Align label design with compliance and audit requirements. Whether it’s maintaining sterility in cleanrooms, ensuring traceability through barcode readability, or validating indicator performance in sterilization, the LabelBuilder makes sure quality-critical details are documented up front.

Purchasing agents

Reduce costly misorders and rework by capturing specifications clearly before an order is placed. Instead of going back and forth between departments to clarify needs, purchasing can submit a LabelBuilder request knowing it reflects engineering and QC input. This leads to smoother procurement and predictable performance once labels arrive.

How to use the LabelBuilder

The LabelBuilder is designed to help you communicate your requirements in a structured way, without requiring you to be a label materials expert. Think of it as a guided conversation starter. Here’s how to get the most out of it:

1. Start with your critical needs

Begin by selecting the requirements that matter most for your environment. For example, if your labels must withstand autoclaving, cryogenic storage, or chemical exposure, check those boxes first. Building from your top priorities ensures the final solution is engineered around the conditions that can’t be compromised.

2. Move through each category

The tool is divided into three sections: material construction, special features, and configuration. Work through them step by step. Each selection helps narrow down the material and design choices that will work for your use case.

3. Pay attention to exclusions

If an option disappears in the LabelBuilder, it’s because you’ve selected another design option that excludes it. For example, because direct thermal printing relies on heat printing techniques, it can’t be paired with high heat resistance. This is why it works best to choose your highest priority options first.

4. Get extra context with info tips

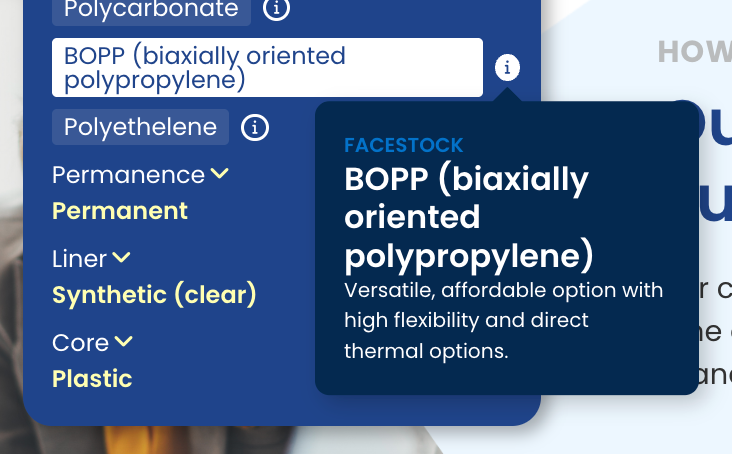

Next to many fields you’ll see an information icon. Hovering over these icons will provide detailed explanations, including definitions, use cases, and potential trade-offs.

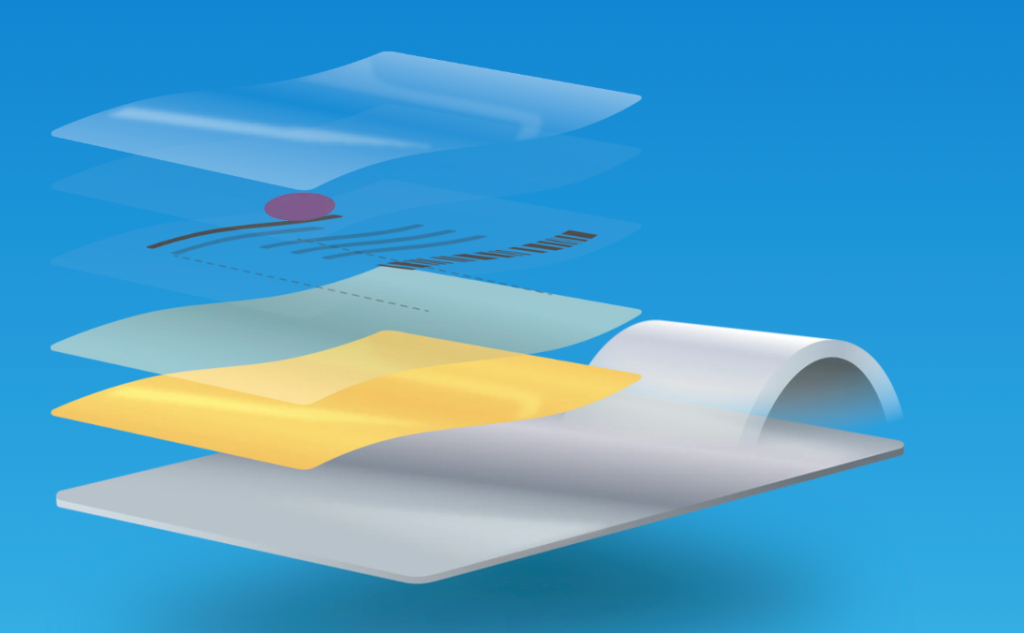

5. Leverage the visual layer display

As you make selections, the LabelBuilder shows a visual representation of every layer in the label construction — from application surface to adhesive to finish, including optional coatings. This makes it easy to understand how your label will be built and how each choice impacts performance.

6. Leave blanks if you’re unsure

If you’re not certain about a particular parameter, don’t worry. Just leave it blank. Our engineers will review your request and follow up to clarify. It’s better to provide accurate details about what you know — such as temperatures, surfaces, or regulatory constraints — than to guess on technical specifications.

7. Submit and collaborate

After you’ve made your selections, submit your quote request. A CleanMark engineer will review your inputs, confirm any open questions, and provide a tailored recommendation. We always provide samples so you can test on-site to ensure your labels function flawlessly in your unique processes.

Example LabelBuilder designs

Wondering what a semiconductor cleanroom lab label might look like? Or a fill and finish pharma label? Take a look at these example LabelBuilder designs and then go make your own!

Easy-tear ISO 5 cleanroom label

Simpler is better. Especially when you’re avoiding contamination. These easy-tear cleanroom labels allow you to tear off exactly the number of labels you need and keep track of your trash with a brightly colored liner.

And, they feature high clarity and high black optical density for barcodes or QR code thermal printing inside a cleanroom (which conveniently requires no ribbon and no additional required cleanroom compatible consumables). Plus, they remove with no residue when you’re finished using them.

Material construction

- Finish: Matte

- Print level: Partially pre-printed

- Print technology: Direct thermal

- Permanence: Removable

- Liner: Synthetic (colors)

Special features

- Clean/aseptic: Cleanroom

Configuration

- Variable printing: QR code

- Perforation: Yes

- Label shape: Square/rectangle

- Label dimensions: 2” x 3”

Thermal transfer labels that can withstand the autoclave

Think thermal transfer labels can’t survive the autoclave? Think again. This label is designed for enhanced ink adhesion through the autoclave process so your thermal transfer printing and indicator ink stay intact during your product’s autoclave cleaning process.

It features a heat, chemical, and moisture resistant baseline as well as a larger size for additional details and a large process indicator for quick visual inspection.

Material construction

- Finish: Matte

- Print level: Partially pre-printed

- Print technology: Thermal transfer

- Permanence: Permanent

- Liner: Synthetic (clear)

Configuration

- Perforation: Yes

- Roll core size: 3in

- Label shape: Square/rectangle

- Label dimensions: 2” x 1”

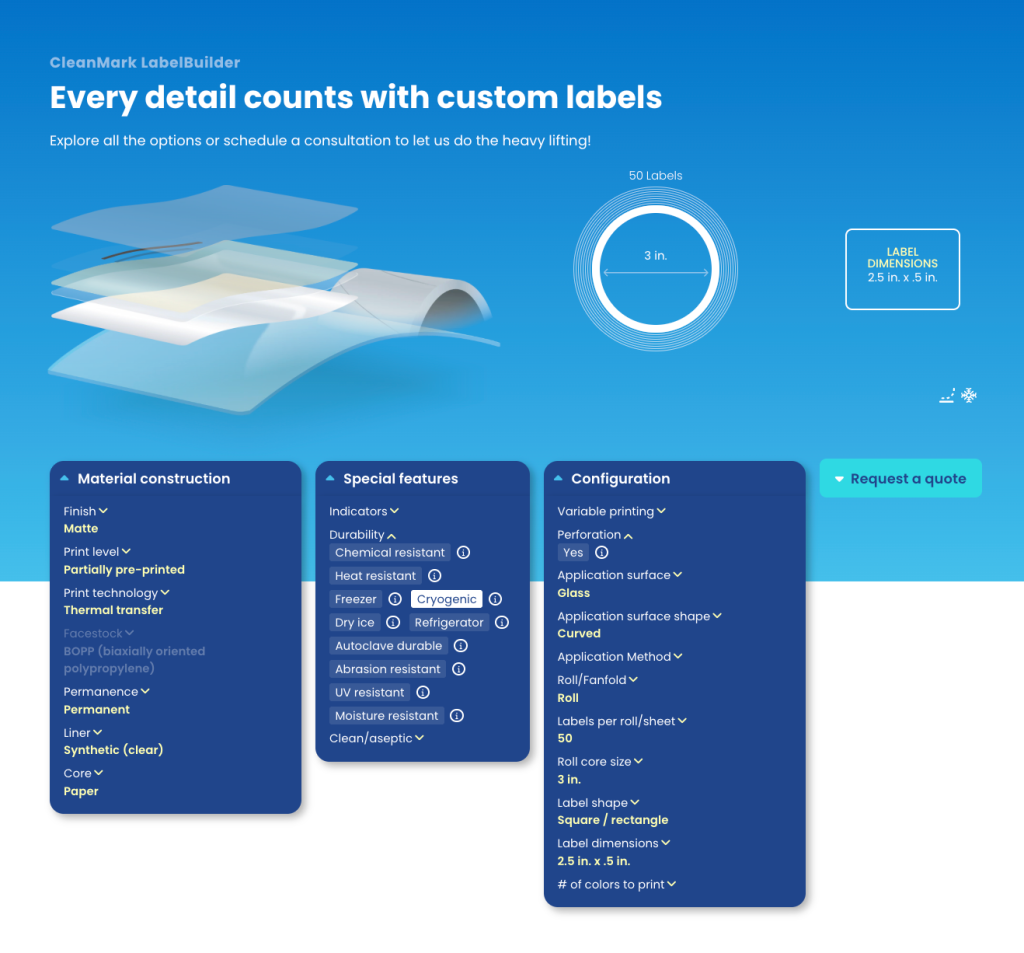

Cryo storage labels that stay put on small vials

Cryogenic storage puts label adhesives to the test! This label is designed specifically to stay permanently adhered in ultra-low temperatures — even around tight curves like vials or syringes. It’s thermal printable with durable ribbon for temperature resistance and can be auto applied.

Material construction

- Finish: Matte

- Print level: Partially pre-printed

- Print technology: Thermal transfer

- Permanence: Permanent

- Liner: Synthetic (clear)

- Core: Paper

Special features

- Durability: Cryogenic

Configuration

- Perforation: No

- Application surface: Glass

- Application surface shape: Curved

- Roll core size: 3in

- Label shape: Square/rectangle

- Label dimensions: 2.5” x .5”

Next steps to custom label success

The LabelBuilder is not the final word on your label design — it’s the starting point. Once you submit your requirements, CleanMark’s team reviews them with you, validates assumptions, and provides prototypes or production samples. The result is a label solution tuned to your exact environment, whether that’s a semiconductor fab, biotech cleanroom, or food manufacturing line.

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

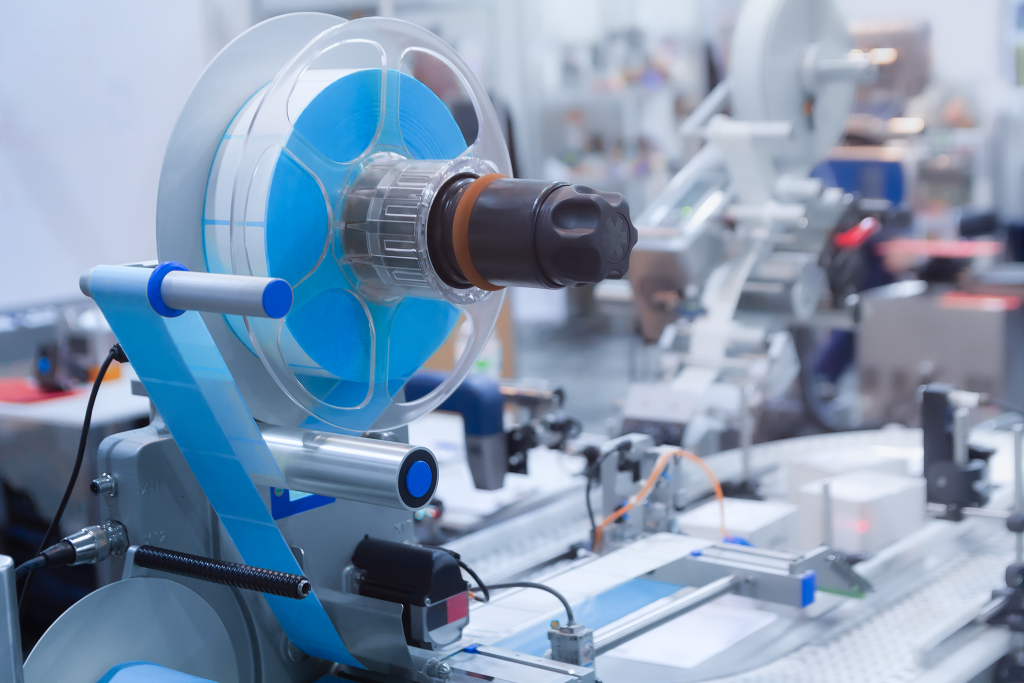

The automation label: materials and construction matter

Why your automated label applicator and labels should be designed together

How automated labeling changes your label needs

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.