Cleanroom labels optimized for your operational needs

CleanMark’s cleanroom labels protect your sensitive environments and are tailored to your exact operational needs so you know they’ll function flawlessly.

Order now

- Give us some initial information

- Review and test your label

- Production and shipping

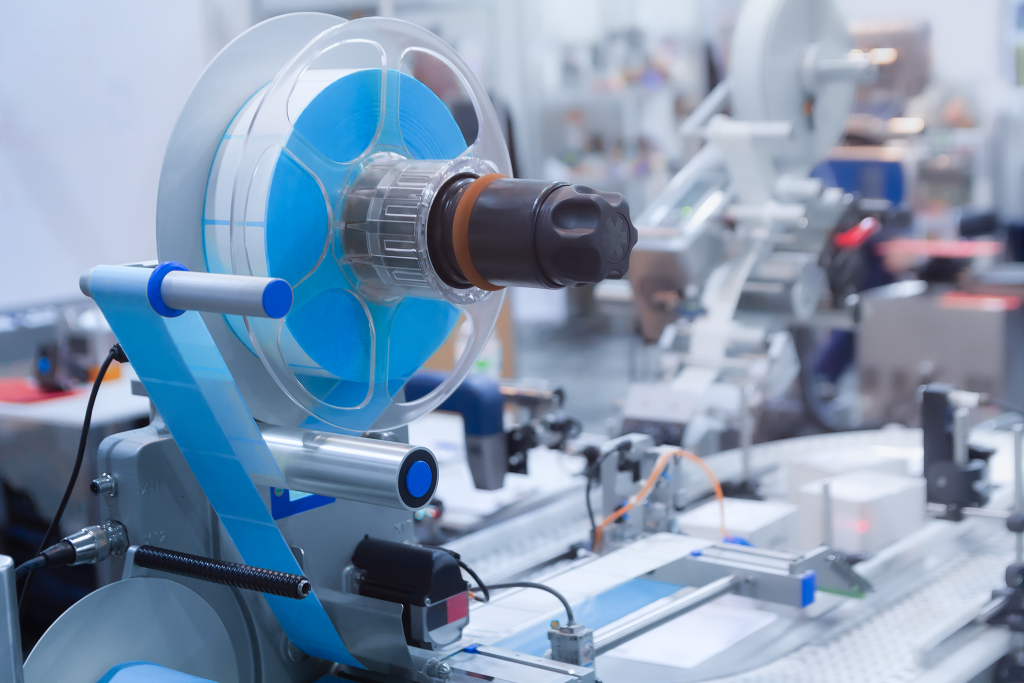

Cutting-edge cleanroom label technology safeguards your sensitive environments

For 40 years, CleanMark has worked with leaders in the semiconductor and pharmaceutical industries to create cleanroom label solutions that protect sensitive environments while optimizing operational processes.

Low particle generation

CleanMark’s cleanroom labels are processed in our own cleanroom from materials designed to prevent particle shedding.

Low outgassing materials

Our low-outgassing materials protect clean environments from VOCs and other contaminating gasses.

Anti-static properties

ESD-safe materials ensure your cleanroom won’t be disrupted by electrostatic discharge.

Chemical resistance

Chemical resistant coatings withstand cleanroom cleaning agents and solvents, ensuring legibility and adhesion.

Residue-free adhesion

CleanMark’s specialized adhesives prevent residue that could trap contaminating particles.

Our most popular cleanroom labels

Choose one of these popular labels, or work with our R&D team to create a fully customized solution.

Wafer box labels

for reliable tracking with no sticky residue

Chemical labels

to increase safety and support compliance

Equipment and tracking logs

to boost efficiency and reduce risk

Gowning room labels

to speed operations and ensure safety

Product tracing labels

for audit readiness and manufacturing efficiency

Waffle tray labels

to reduce errors and increase productivity

Increase efficiency with custom cleanroom labels

CleanMark’s cleanroom labels are designed for durability, reliability, and seamless integration into your processes so you never face delays or contamination.

Boost process efficiency

Clean, durable labeling ensures accurate identification of equipment, materials, and workflows in sensitive areas — reducing errors and improving operational efficiency.

Prevent contaminating residue

Adhesive residue can compromise cleanroom integrity. CleanMark’s specialized cleanroom label adhesives offer residue-free adhesion — whether permanent, temporary, or removable — so your surfaces stay clean.

Dependable identification

From tracking critical components to labeling sterile packages, CleanMark’s cleanroom labels can be designed to withstand the toughest environments while remaining legible and adhered.

Choose the right cleanroom labels for the job

CleanMark offers a variety of different cleanroom labels, including a fully customized option.

Removable

From tracking wafer boxes to labeling equipment with inspection info, our removable cleanroom labels stay adhered as intended until you’re ready to remove them. And they leave no messy residue.

Printable

Get the flexibility of ink jet, laser, direct thermal or thermal transfer printing without jeopardizing your clean environments. We offer both partially pre-printed and blank printable cleanroom labels.

Durable

Chemical exposure, extreme temperatures, and abrasion are no match for our durable cleanroom labels. We offer a wide range of label materials to withstand your toughest environmental challenges.

Sterile

When you need to meet two high standards, CleanMark’s sterile cleanroom labels are the solution. These labels are processed in our ISO 5 cleanroom then gamma or e-beam sterilized.

ISO 9001:2015 compliant

Our cleanroom labels are engineered to excel in controlled environments, adhering to ISO-5 cleanroom standards by providing ultra-low particle and residue-free performance. CleanMark is an ISO-certified facility, and our cleanroom compatible labels are produced in a Class 100 environment.

Boost efficiency with labels that are clean and sterile

Highly regulated products often pass through both clean and aseptic environments during manufacturing. CleanMark dual-purpose clean, sterile labels give you the best of both worlds, ensuring compliance, minimizing risk, and speeding production.

Explore other CleanMark cleanroom and sterile products

Cleanroom tape

Useful for sealing packaging and protective garments and marking floors

Cleanroom tags

Flexible, contamination-free identification

Sterile labels

Irradiated to eliminate microbial contamination

Autoclave indicator labels

Easy-to-read results based on steam, temperature, and time

ETO indicator labels

Color change under pressure, exposure, temperature and duration consistent with sterilization

Gamma indicator labels

Color change under irradiation dose process consistent with sterilization

Join the list of innovative companies partnering with CleanMark

Looking for more information about labeling technology and applications?

Optimizing lab labels for high-performance aseptic operations: hybrid sterile + cleanroom-compatible labels

Semiconductor clean room labels ensure traceability, compliance, and contamination control

Medication labels: why customization matters

Stay up to date on the latest cleanroom label technology

From new materials to advances in adhesives, we’ll keep you informed about technology that can make your processes run more smoothly.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.