Ensure compliance and customer satisfaction with custom food and beverage labels

Your tracking and consumer info labels need to withstand everything the production line throws at them — moisture, cold, heat, chemicals. CleanMark custom food and beverage labels withstand it all.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

Off-the-shelf labels increase risk and slow processing. Custom is better.

Food and beverage processing relies on accurate tracking and labeling to keep the line moving and prevent regulatory fines. Standard labels fail often and can’t multi-task. What you need is a label customized to meet all your technical requirements.

- Designed by engineers with food and beverage expertise

- Engineered for extreme durability

- Backed by a team committed to operational success

Increase processing efficiency and ensure compliance

CleanMark’s multi-faceted labeling approach can maximize efficiency, ensure quality, and prove compliance — all with one custom label.

Decrease processing times

Our durable labels help you streamline processing by tracking batches easily and reliably.

Maximize quality

From tamper-evident elements to hand-writable inspection space, we can customize your labels to incorporate effective quality control measures.

Ensure compliance

Protect your customers and prevent regulatory fines with durable safety, information, and tracking labels that prove compliance.

Put labeling innovation to work for you

CleanMark has been leading the way in labeling solutions for 40 years. From cold-chain to tamper prevention, we have the label technology to ensure your products are safe and successful.

Durability

Food and beverage labels have to withstand a lot during processing, packaging, and shipping. We design every label with custom adhesives, facestock, and coatings to ensure they’ll withstand everything you throw at them.

Learn more

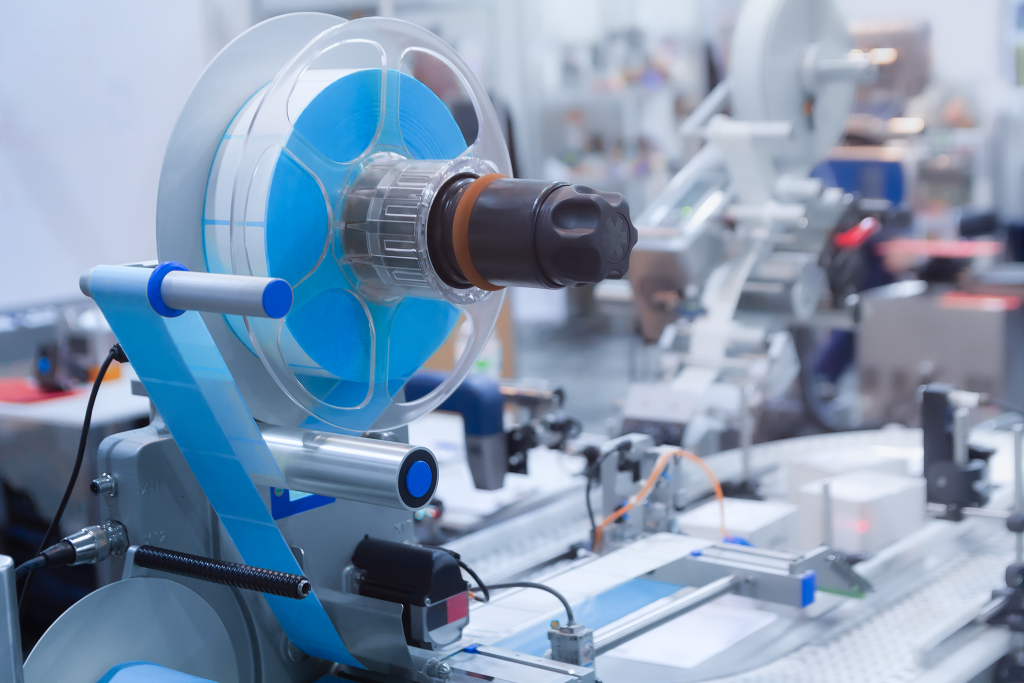

Automatic application reliability

Applicator machine jams cost valuable production time. Our label adhesives and liners are expert-engineered to work flawlessly with your specific applicator machine.

Learn more

Printer compatibility

We offer variable and static preprinting and our labels are compatible with most direct thermal, thermal transfer, inkjet and laser printers so you can choose the right balance of factory and on-site printing.

Learn more

Solutions for all your food and beverage label needs

From extreme temperature resistance to tamper-evident label elements, we’ve got you covered.

Chemical resistant labels

Resistant to degradation caused by harsh chemicals

Heat resistant labels

Maintain integrity and legibility at high temperatures

Freezer labels

Designed for temperatures between 0°C and -40°C

Cryogenic labels

Ideal for liquid nitrogen environments of -196°C

Refrigerator labels

Cold chain labels designed for use between 2°C to 8°C

Dry ice labels

Optimized for ultra-low temp lab freezers between -40 °C and -80 °C

Waterproof labels

Maintain integrity and legibility in high-moisture environments

Direct thermal labels

Optimized for use with direct thermal printers like Zebra and DYMO

Thermal transfer labels

Perfect for Zebra, DYMO and other thermal transfer printers

Laser labels

Ideal for detailed text and graphics printed on major laser printers

Inkjet labels

Optimized for vibrant colors printed on major inkjet printers

Let us take the guesswork out of food and beverage labels

One of our food and beverage labeling experts is waiting to partner with you.

- Tell us your needs

- We design an efficient, reliable solution.

- You never think about labels again.

Looking for more information about food and beverage labels?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

The automation label: materials and construction matter

How automated labeling changes your label needs

5 steps to tame the change management process

We’ve been partnering with leading companies for 40 years

Stay up to date on labeling advances in the food and beverage industry

From QR traceability to new tamper evidence elements and cold-resistant adhesives, CleanMark keeps you up to date on the labeling solutions that make your work easier.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.