Comprehensive labeling solutions for the oil and gas industry

From safety labels to calibration tags, CleanMark custom labels ensure safety, increase efficiency, and function reliably even in the harshest environments.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

Standard labels just can’t hack it in the oil and gas world

The heat, chemicals exposure, and abrasion of oil and gas environments are too much for most off-the-shelf labels. CleanMark’s custom labels withstand extreme environments and can be custom designed to multi-task through your processes, saving time and resources.

- Designed by engineers with energy sector expertise

- Engineered for extreme durability

- Backed by a team committed to long-term success

Learn more about how we customize oil and gas industry labels

With CleanMark custom labels, you get durability and functionality

Unlike standard labels that are designed for one purpose, CleanMark’s custom labels are multi-functional, so you can add batch info, safety warnings, and even proof of inspection all on one incredibly durable label.

Optimize operations

CleanMark labels streamline operations by quickly and reliably conveying essential information, from asset management to safety inspections or batch tracking.

Prioritize safety

Custom safety labels provide clear hazard communication, improve emergency response time, and minimize human error, leading to fewer accidents and injuries.

Maintain compliance

Always be audit ready with CleanMark’s durable inspection, environmental, and safety labels.

Put labeling innovation to work for you

CleanMark has been leading the way in labeling solutions for 40 years. From heat resistance to chemical-resistant adhesives, we have the label technology to ensure your products are safe and successful.

Extreme durability

There’s no environment too extreme for CleanMark to label. Our team of engineers has worked with customers to create materials that withstand the harshest conditions. Whatever you need, we’ll find a way to make it.

Learn more

Specialized adhesives

Labels have to stay stuck in order to do their job. CleanMark’s custom-engineered adhesives are designed to reliably adhere to difficult surfaces in difficult environments.

Learn more

Long-term legibility

CleanMark’s variety of printing and finish options ensure your labels remain legible for the long run, despite abrasion, chemical exposure, and extreme temperatures.

Learn more

Solutions for all your oil and gas industry label needs

From extreme temperature resistance to tamper-evident label elements, we’ve got you covered.

Chemical resistant labels

Resistant to degradation caused by harsh chemicals

Heat resistant labels

Maintain integrity and legibility at high temperatures

Freezer labels

Designed for temperatures between 0°C and -40°C

Cryogenic labels

Ideal for liquid nitrogen environments of -196°C

Refrigerator labels

Cold chain labels designed for use between 2°C to 8°C

Dry ice labels

Optimized for ultra-low temp lab freezers between -40 °C and -80 °C

Waterproof labels

Maintain integrity and legibility in high-moisture environments

Direct thermal labels

Optimized for use with direct thermal printers like Zebra and DYMO

Thermal transfer labels

Perfect for Zebra, DYMO and other thermal transfer printers

Laser labels

Ideal for detailed text and graphics printed on major laser printers

Inkjet labels

Optimized for vibrant colors printed on major inkjet printers

Let us take the guesswork out of oil and gas industry labels

One of our energy sector labeling experts is waiting to partner with you.

- Tell us your needs

- We design an efficient, reliable solution.

- You never think about labels again.

Looking for more information about oil and gas industry labels?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

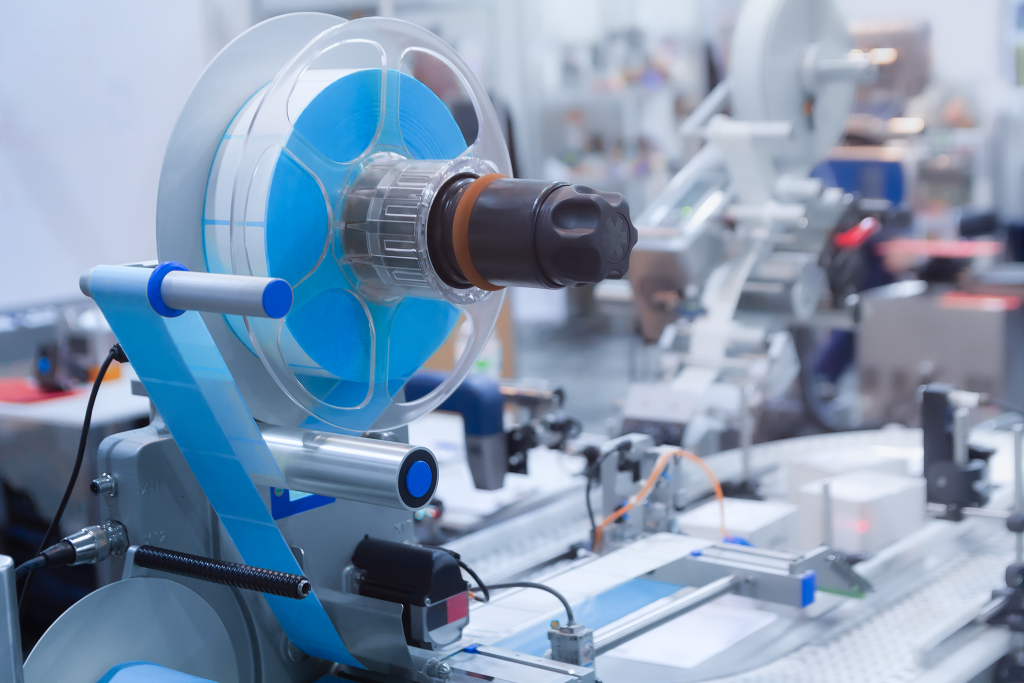

The automation label: materials and construction matter

How automated labeling changes your label needs

5 steps to tame the change management process

We’ve been partnering with leading companies for 40 years

Stay up to date on labeling advances in the energy sector

From hazmat labels to new heat durable adhesives, CleanMark keeps you up to date on the labeling solutions that withstand tough conditions.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.