Advanced label adhesives enhance performance

Don’t settle for standard label adhesives when performance is paramount. Our tech team integrates advanced adhesives designed for your exact process and environment to optimize efficiency and prevent label failure.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

Why choosing the right label adhesive matters

It goes without saying that one major job of a label is to stick to a surface and convey information. But what surface? And for how long?

You need a skilled, experienced label design team at your back to make sure your labels meet all your adhesion needs.

What goes into choosing the right adhesive?

CleanMarks’s tech team considers three main aspects of adhesion when choosing the adhesive for your custom-engineered label:

- Duration

- Surface type

- Environmental factors

Duration of adhesion

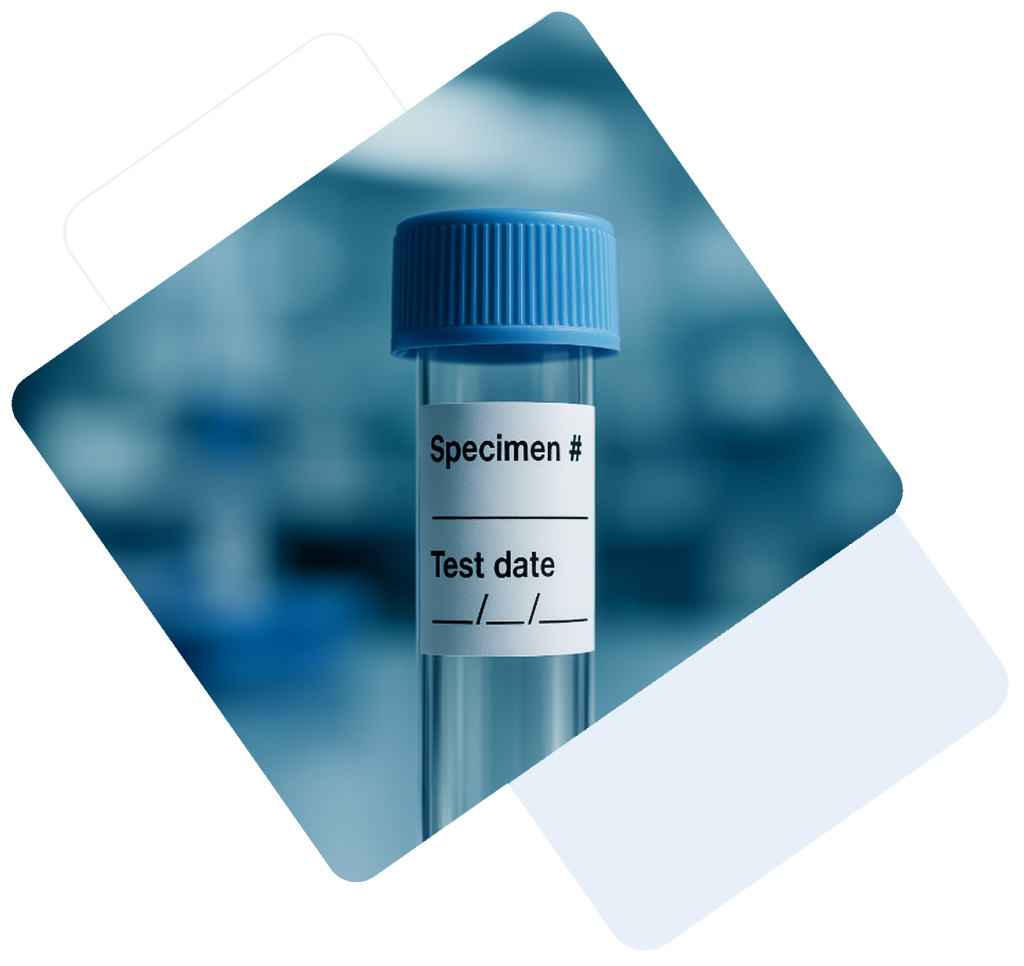

Whether you’re labeling wafer boxes in a semiconductor manufacturing facility or samples in a clinical trial, we’ll choose an adhesive that stays put when and how you need it to.

Permanent

Stay adhered over long periods of time in your specific environment

Repositionable

Adhere when placed, remove without residue, and securely adhere in a new location

Removable

Optimized for secure temporary use and residue-free removable

Surface type

Our tech team is experienced with surfaces that make adhesion difficult, from the tight curves of PCR tubes to low surface energy (LSE) plastics.

Non-flat surfaces

Highly flexible, conformable label materials paired with pressure-sensitive adhesive with strong tack to ensure reliable adhesion, preventing label lift.

LSE materials

Aggressive, high-tack adhesives designed specifically for Low Surface Energy (LSE) surfaces prevents label failure on the most challenging surfaces.

Environmental factors

In research and manufacturing settings, labels often need to withstand extreme conditions like heat and chemical exposure, and they may even need to be applied in those conditions.

Moisture

From hydrophilic adhesives to wet-applied or freezer-grade options, we’ll find the adhesive that works best for your application procedure.

Extreme temps

Our team has the materials knowledge and practical experience to know which adhesive to choose for the most extreme hot and cold conditions.

Chemical exposure

We have access to an array of fluoropolymer-based, silicone, acrylic or epoxy-based chemical-resistant adhesives to ensure adhesion.

Need help choosing the right label adhesive?

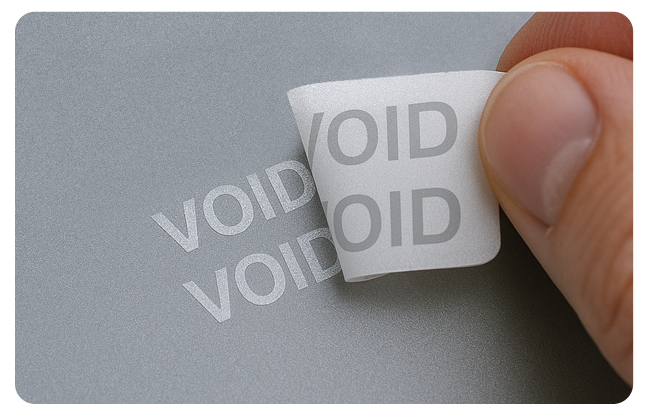

Tamper resistance and void upon removal

When safety matters, tamper resistant adhesives ensure that labels are not altered, removed, or transferred. Our team can help you choose the best tamper-indicating adhesive option.

Evidence of removal

Adhesives can leave behind a “VOID” message, checkerboard pattern, or residue when the label is peeled off.

Re-use prevention

Prevent reapplication or transfer with labels that shred and become unreadable when removal is attempted.

Signs of alteration

Block tampering with adhesives that discolor, warp, or become unreadable if exposed to heat, solvents, or attempts at peeling

Cleanroom-compatible label adhesives

Sensitive cleanroom environments can be jeopardized by the wrong adhesive choice, which is why use cleanroom-specific adhesives when manufacturing our clean labels.

Low outgassing

Silicone-free, low-VOC (volatile organic compound) adhesives prevent contamination of sensitive environments and maintain air purity in research and manufacturing cleanrooms.

Residue-free removable adhesives

Residue-free adhesives remove without leaving residue that could attract dust or compromise cleanliness — perfect for semiconductor manufacturing wafer boats.

Non-particulating adhesives

Prevent shedding or flaking with adhesives engineered to ensure no loose particles enter cleanroom air circulation systems, jeopardizing sensitive processes.

Let us design the perfect label for you

The perfect label isn’t chosen, it’s created. CleanMark puts 40 years of labeling expertise to work for our customers. We research your exact technical and operational needs and then design a label that meets them perfectly.

Join the list of innovative companies partnering with CleanMark

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.