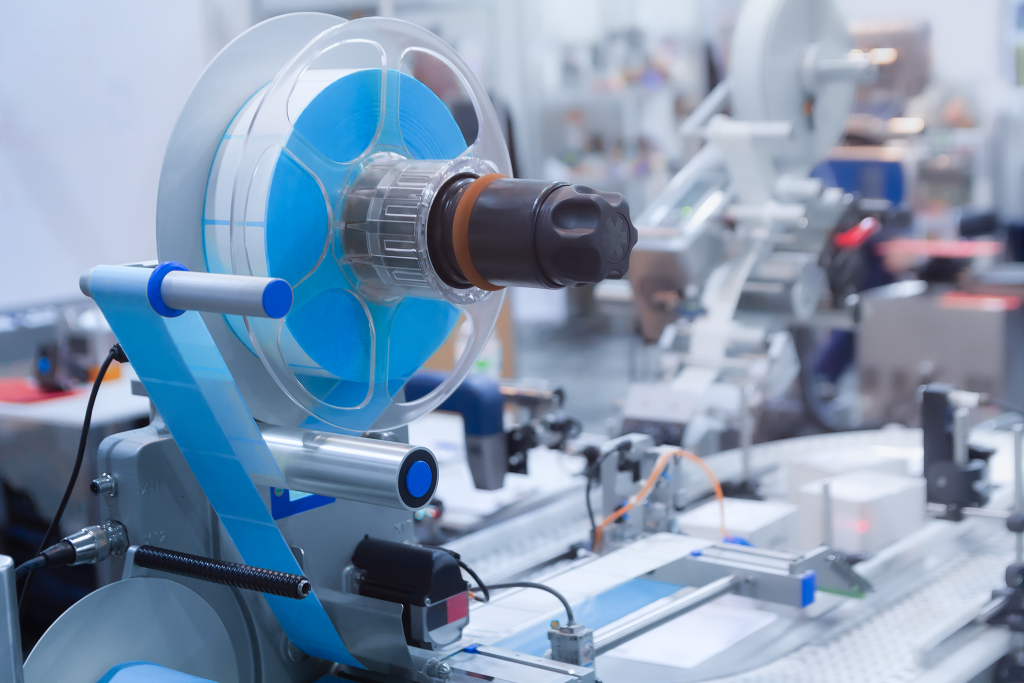

Custom labels for precision processes

Your company isn’t a cookie-cutter company. So it’s no wonder that cookie-cutter labels fail you. CleanMark’s custom labels are expert-engineered to meet the unique specifications of your precision processes.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

What do we mean when we say custom labels?

We mean that whether you already know your exact label parameters or are looking to work with an expert to explore all possible solutions, we’ll engineer a label that works flawlessly in your processes.

- Stress free optimization

- Industry-specific design expertise

- Ongoing support

Our custom label process delivers a custom solution — fast

Our customization process is efficient and effective. Our goal is to take as little of your time as possible and deliver an optimized label solution tailored to your unique needs — and we do it faster than our competitors can produce off-the-shelf labels.

Tell us about your labeling needs

Fill out our initial request form so we know a little more about what you need, from environmental challenges to process requirements.

Meet a CleanMark label expert

You’ll be matched with a label expert with experience in your industry who will work with you to understand your exact requirements and propose labeling solutions.

Review your custom label design

We’ll send over your custom label design for you to review to make sure it meets all of your specifications.

Test custom label samples or prototype

Our sampling process lets you double check that your custom label will work as desired in your real-world scenario. And for more complex labels, we can provide a prototype to ensure optimal functionality.

We produce and ship your new custom label

Our innovative production processes let us deliver custom labels faster than many of our customers deliver off-the-shelf options.

Ready to see what a difference custom labels can make?

Whether you know every technical requirement for your label or are looking for someone to investigate and propose the ideal solution, our label experts are standing by to help.

We’re not just producing cutting-edge labels, we’re inventing them

CleanMark works with customers who are pushing the boundaries of technology, which means we’re constantly imagining new solutions to meet their needs.

CleanMark’s design philosophy is built on 40 years of custom label experience.

We have the ability to call on a broad range of in-house production options using cutting-edge labeling materials and processes. From printing technology to applicator optimization, our holistic approach to label customization means you get a solution that hits the mark every time.

We use a three-factor approach to customization.

- Application

Optimized for hand or machine application - Adhesion

Selected based on environment, surface, and permanence - Print

Chosen based on durability, resolution, color, and on-site printing requirements

Join the list of innovative companies partnering with CleanMark

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

Achieve cleanroom manufacturing traceability with custom tags

Invisible Sentinel: Save time with multi-purpose autoclave labels

Which label is right for your label applicator machine?

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.