Build customer trust with CleanMark sterile indicating medical device labels

Your customers need to know your product is sterile. Our gamma irradiation indicating medical device labels provide that assurance and can be customized to highlight brand and product information — all on one label.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

A standard label can’t do what you need it to

When you’re designing and manufacturing medical devices that are pushing the boundaries of healthcare, you’re not going to find an off-the-shelf label that meets your product requirements and provides customers with assurance of sterility. You need a CleanMark custom label.

- Designed by engineers with medical device expertise

- Optimized for multi-factor use

- Backed by a team committed to your continuing innovation

Protect patient health and boost productivity with custom labels

You’re thinking outside the box, and so are we. CleanMark labeling technology rises to meet the quickly evolving needs of the medical device industry.

Demonstrate sterility

Give your customers peace of mind that your product is sterile and convey other important product information with CleanMark’s multi-purpose sterile indication labels.

Ensure compliance

Our custom labels give you the flexibility to include UDIs, bar or QR codes, and any other information needed for inventory and regulatory tracking.

Stay on schedule

Think off-the-shelf is faster? Think again. CleanMark designs, produces, and ships labels that actually meet your needs faster than our competitors can send you their generic version.

Labels as innovative as your medical devices

CleanMark has been pioneering labeling technology for 40 years. We thrive on the challenge of creating new labeling solutions to meet the evolving needs of our high-tech customers.

Sterilization indication

Add autoclave, gamma irradiation, or EtO sterilization indicator ink to your custom label to demonstrate that sterilization processes have been successfully completed.

Learn more

Durability

Medical device labels have to remain legible in extreme conditions, be they inside or outside the human body. CleanMark labels withstand moisture, head, cold, chemicals, and anything else you throw at them.

Learn more

Biocompatibility

We process our sterile labels in an ISO 5 cleanroom, sterilize them using gamma radiation or EtO, and package them to ensure they arrive at your facility free of contamination.

Learn more

Solutions for all your medical label needs

From biocompatible tracking to sterilization indicators, we have every label you need to develop and produce your medical device.

Sterile labels

Irradiated to eliminate microbial contamination

Autoclave indicator labels

Easy-to-read results based on steam, temperature, and time

ETO indicator labels

Color change under pressure, exposure, temperature and duration consistent with sterilization

Gamma indicator labels

Color change under irradiation dose process consistent with sterilization

Cleanroom labels

No particulate contamination or outgassing

Cleanroom tape

Useful for sealing packaging and protective garments and marking floors

Cleanroom tags

Flexible, contamination-free identification

Chemical resistant labels

Resistant to degradation caused by harsh chemicals

Heat resistant labels

Maintain integrity and legibility at high temperatures

Freezer labels

Designed for temperatures between 0°C and -40°C

Cryogenic labels

Ideal for liquid nitrogen environments of -196°C

Refrigerator labels

Cold chain labels designed for use between 2°C to 8°C

Dry ice labels

Optimized for ultra-low temp lab freezers between -40 °C and -80 °C

Waterproof labels

Maintain integrity and legibility in high-moisture environments

Direct thermal labels

Optimized for use with direct thermal printers like Zebra and DYMO

Thermal transfer labels

Perfect for Zebra, DYMO and other thermal transfer printers

Laser labels

Ideal for detailed text and graphics printed on major laser printers

Inkjet labels

Optimized for vibrant colors printed on major inkjet printers

Let us take the guesswork out of medical device labels

One of our medical device labeling experts is waiting to partner with you.

- Tell us your needs

- We design an efficient, reliable solution.

- You never think about labels again.

Get real-world insight into the benefits of custom-engineered medical device labels

CleanMark builds lasting partnerships with medical device manufacturers to address their specific labeling needs. Explore our case studies to see how CleanMark’s tailored solutions overcome real-world operational challenges.

Invisible Sentinel | Save time and resources with multi-purpose autoclave labels

Ionis Pharmaceuticals | Optimizing equipment management with QR code labels

Access Biologicals | Integrated gamma labels with cryogenic adhesive

We’ve been partnering with medical device leaders for 40 years

Looking for more detailed information about medical device labels?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

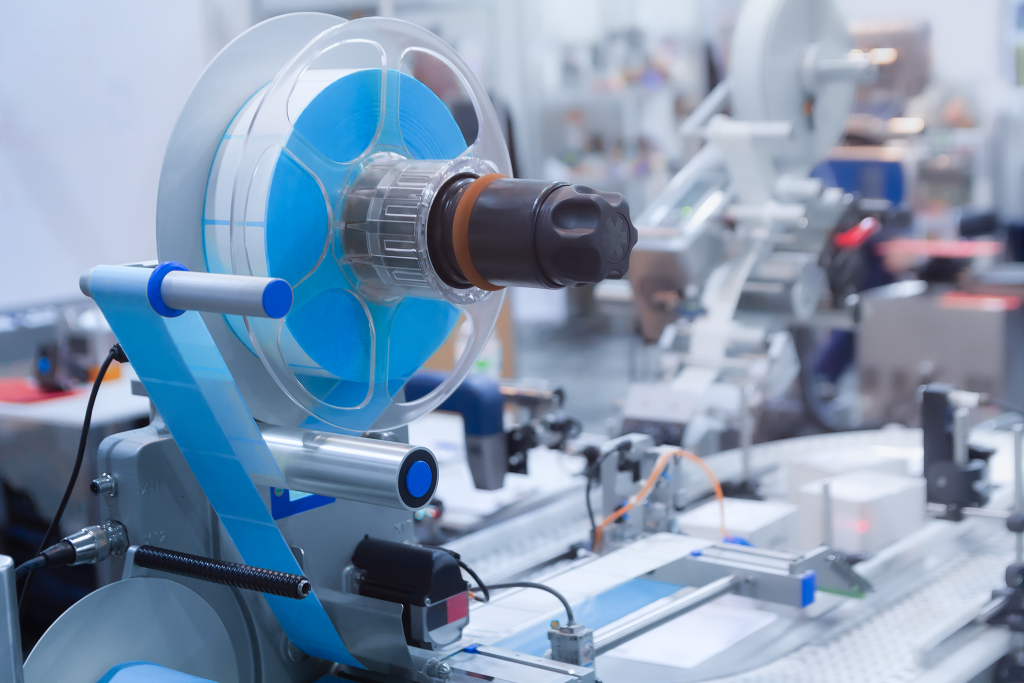

The automation label: materials and construction matter

How automated labeling changes your label needs

CleanMark Labels: 40 years solving the impossible

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.