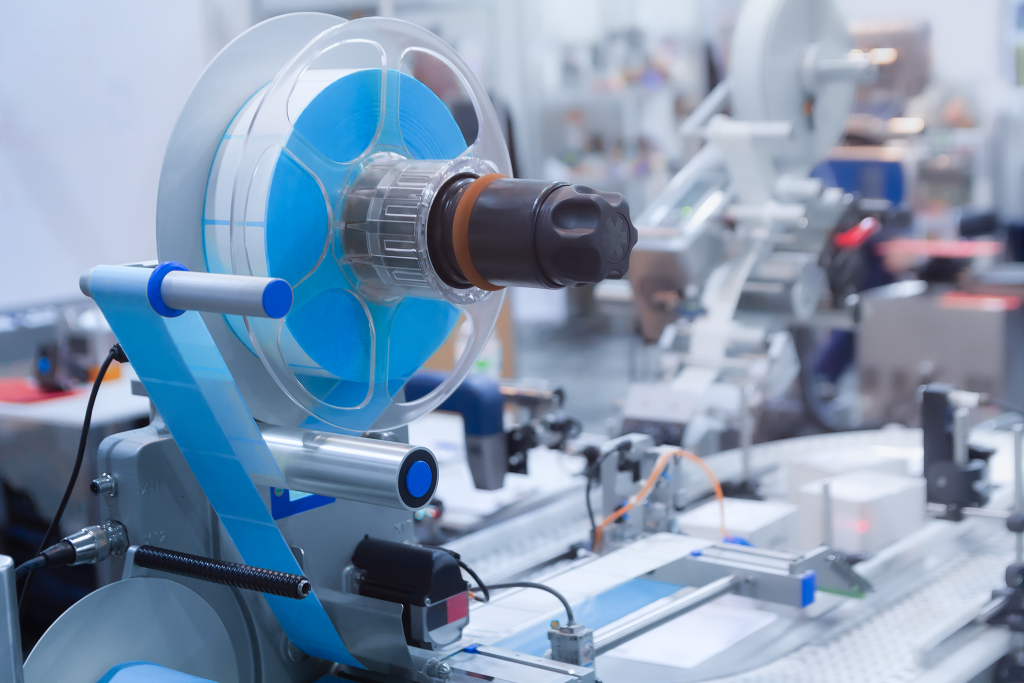

Printable labels

In precision processes, there’s no room for errors and slowdowns because of printer-label incompatibility. Whether you need printable labels that use direct thermal, thermal transfer, inkjet, or laser label printing, we have you covered.

Order now

- Give us some initial information

- Review and test your label

- Production and shipping

Printable labels optimized for your existing setup

Whether you’re wanting fully pre-printed labels, blank labels to print on site, or any combination in between, CleanMark’s label experts will build a label that’s perfectly suited to your printing setup.

Compatibility

CleanMark printable labels are compatible with most popular direct thermal, thermal transfer, inkjet, and laser printers.

Durability

Choose from a wide range of high-tech materials that ensure legibility under even the harshest temperature, chemical, moisture, or abrasive conditions.

Information layout

Our labels are thoughtfully designed to leverage the speed of pre-printing for evergreen elements and the flexibility of on-site printing for more fluid info.

Put our printable labels to work for you

Take advantage of our broad range of printing technologies and expertise to build a printable label that meets your every need.

Preprinting, on-site printing, or the best of both

CleanMark offers three different forms of printing, so you can choose the approach that best meets your needs.

Preprinting

Pre-printing is faster, and it’s more cost effective on the front end. It’s the perfect choice for labels that convey pre-established information. We can do both static and variable runs.

Printable labels

On-site printing offers unparalleled flexibility. It’s often the right choice for fast-changing information like sample info, process tracking, or information that may change with little notice.

The best of both

Choosing to pre-print some information and print (or handwrite) other information on site is the best of both worlds. We can partially print labels that you then print on-site during your operational processes.

Thermal, inkjet, or laser printing

Choosing the right printing method for your printable labels ensures legible, durable results every time.

Direct thermal

With direct thermal printing, no ink or ribbon is required, the label material itself is heat sensitive, changing color when exposed to heat. This method is highly chemical resistant and produces crisp text at small sizes.

Thermal transfer

Thermal transfer printing, which uses a heated ribbon and ink, is a highly durable option that can be used on a broad range of label materials, including synthetics like polyimide.

Inkjet

Inkjet delivers high-resolution printing with vibrant colors and sharp images and can be used with a broad range of label materials. This method is perfect for applications that require detailed graphics and full-color prints.

Laser

Laser printing produces sharp, high-resolution printing. It’s a great choice for scenarios that require crips, clear text and graphics, and is highly resistant to smudging, fading, and abrasion.

Read to optimize your printable labels? Order now!

What if I need printable labels that are heat resistant or sterile?

Printability is just one of a number of features that need to be optimized for a label or tag to perform well in your processes. We consider them all.

Let us design the perfect printable labels for you

The perfect label isn’t chosen, it’s created. CleanMark puts 40 years of labeling expertise to work for our customers. We research your exact technical and operational needs and then design a label that meets them perfectly.

Join the list of innovative companies partnering with CleanMark

Looking for more information about labeling technology and applications?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

5 ways thermal printing labels save you time and resources

Should your lab use thermal transfer printable labels?

Ionis Pharmaceuticals | Optimizing equipment management with QR code labels

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.