CleanMark’s pharmaceutical labels stand up to the toughest lab conditions

From autoclaving to cold storage, you need a durable label that can do double or triple duty when necessary, indicating sterility, tracking product, and ensuring compliance. Our custom labels do it all.

Upgrade to custom labels

- Give us some initial information

- Talk to a label expert

- Review and test your custom label

- Production and shipping

Custom pharmaceutical labels outpace off-the-shelf options

Whether it’s reliably adhering to tiny PCR tubes, withstanding autoclaving, or process multitasking, standard labels deliver mediocre results. CleanMark custom labels are specially engineered with the exact shape, size, durability, and sterility factors you need.

- Designed by engineers with pharmaceutical expertise

- Optimized for pharmaceutical processes

- Backed by a team committed to your productivity

We focus on labels so you can focus on pharmaceutical breakthroughs

At the cutting edge of pharmaceutical research, there’s no room for error. CleanMark’s custom pharmaceutical labels ensure patient safety, process efficiency, and regulatory compliance.

Prevent contamination

Our sterile labels are processed in CleanMark’s ISO 5 cleanroom, sterilized using gamma irradiation, then packaged so they don’t carry contaminating bacteria into your lab.

Ensure sterilization

Knowing your sterilization processes have successfully been completed is essential for patient health and regulatory compliance. CleanMark offers indicators for autoclave, gamma, and EtO sterilization techniques.

Safeguard essential information

CleanMark pharmaceutical labels withstand cleaning, sterilization, abrasion, and cold storage, remaining adhered and legible to convey essential safety and operational information.

We’re at the front edge of pharmaceutical label technology

CleanMark is a pioneer in labeling technology. Our deep experience and expertise in the pharmaceutical industry means we’re not just providing cutting edge pharmaceutical labels, we’re inventing them.

Durable adhesives

Pharmaceutical labels are only useful if they stay stuck despite moisture, heat, cold, chemicals, and other harsh conditions. CleanMark continues to develop new adhesives that outperform the competition in the most extreme environments.

Learn more

Versatile sterilization indication

Gone are the days of adding indicator tape to an existing label. CleanMark can integrate autoclave, gamma, or EtO indicating strips or dots with other essential label information so you only have to apply once.

Learn more

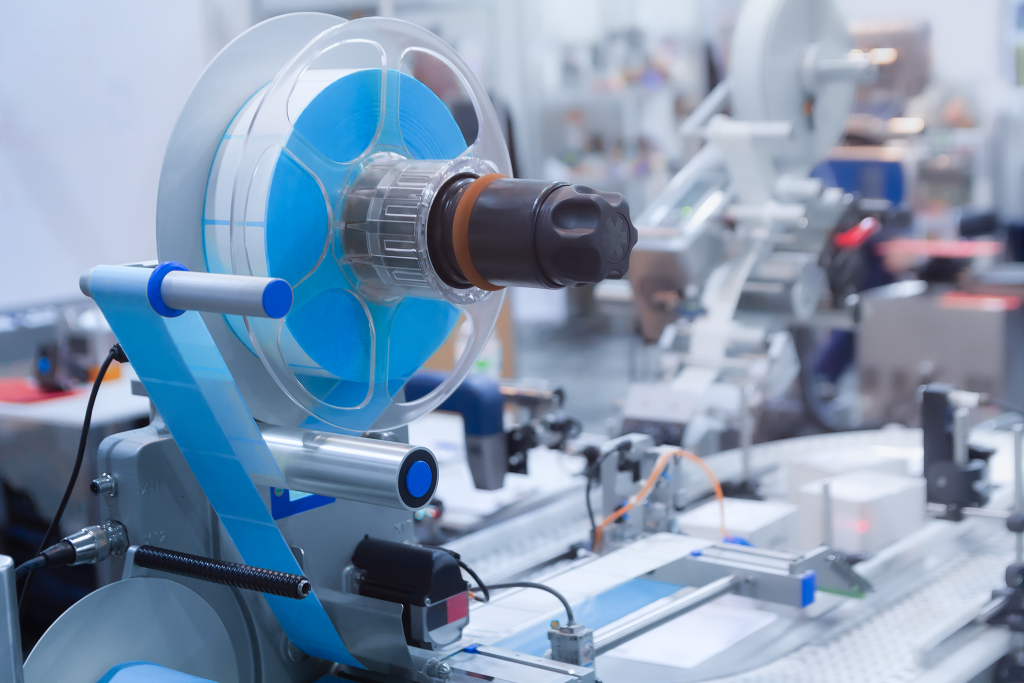

Printer and applicator compatibility

Our pharmaceutical labels are compatible with all major direct thermal, thermal transfer, inkjet, and laser printers. They’re also optimized for machine application.

Learn more

Solutions for all your pharmaceutical label needs

From sterile indicating dots to cold-storage durable labels, we have your pharmaceutical labeling needs covered.

Cleanroom labels

No particulate contamination or outgassing

Cleanroom tape

Useful for sealing packaging and protective garments and marking floors

Cleanroom tags

Flexible, contamination-free identification

Sterile labels

Irradiated to eliminate microbial contamination

Autoclave indicator labels

Easy-to-read results based on steam, temperature, and time

ETO indicator labels

Color change under pressure, exposure, temperature and duration consistent with sterilization

Gamma indicator labels

Color change under irradiation dose process consistent with sterilization

Chemical resistant labels

Resistant to degradation caused by harsh chemicals

Heat resistant labels

Maintain integrity and legibility at high temperatures

Freezer labels

Designed for temperatures between 0°C and -40°C

Cryogenic labels

Ideal for liquid nitrogen environments of -196°C

Refrigerator labels

Cold chain labels designed for use between 2°C to 8°C

Dry ice labels

Optimized for ultra-low temp lab freezers between -40 °C and -80 °C

Waterproof labels

Maintain integrity and legibility in high-moisture environments

Direct thermal labels

Optimized for use with direct thermal printers like Zebra and DYMO

Thermal transfer labels

Perfect for Zebra, DYMO and other thermal transfer printers

Laser labels

Ideal for detailed text and graphics printed on major laser printers

Inkjet labels

Optimized for vibrant colors printed on major inkjet printers

Let us take the guesswork out of pharmaceutical labels

One of our pharmaceutical labeling experts is waiting to partner with you.

- Tell us your needs

- We design an efficient, reliable solution.

- You never think about labels again.

Get real-world insight into the benefits of custom-engineered pharmaceutical labels

CleanMark partners longterm with our pharmaceutical customers to solve their unique labeling challenges. Check out these case studies to get an in-depth look into how CleanMark’s customization process solves real-world operational challenges.

Invisible Sentinel | Save time and resources with multi-purpose autoclave labels

Ionis Pharmaceuticals | Optimizing equipment management with QR code labels

Access Biologicals | Integrated gamma labels with cryogenic adhesive

We’ve been partnering with pharmaceutical leaders for 40 years

Looking for more detailed information?

Explore case studies, articles, guides and more in our extensive library of labeling resources.

The automation label: materials and construction matter

How automated labeling changes your label needs

CleanMark Labels: 40 years solving the impossible

Stay up to date on labeling advances in your industry

From white papers to industry surveys and ebooks, we’ll make sure you’re informed about the latest technology that can make your operations more efficient and less stressful.

Have more questions? We have answers!

Read on for answers to our customers’ most common questions.